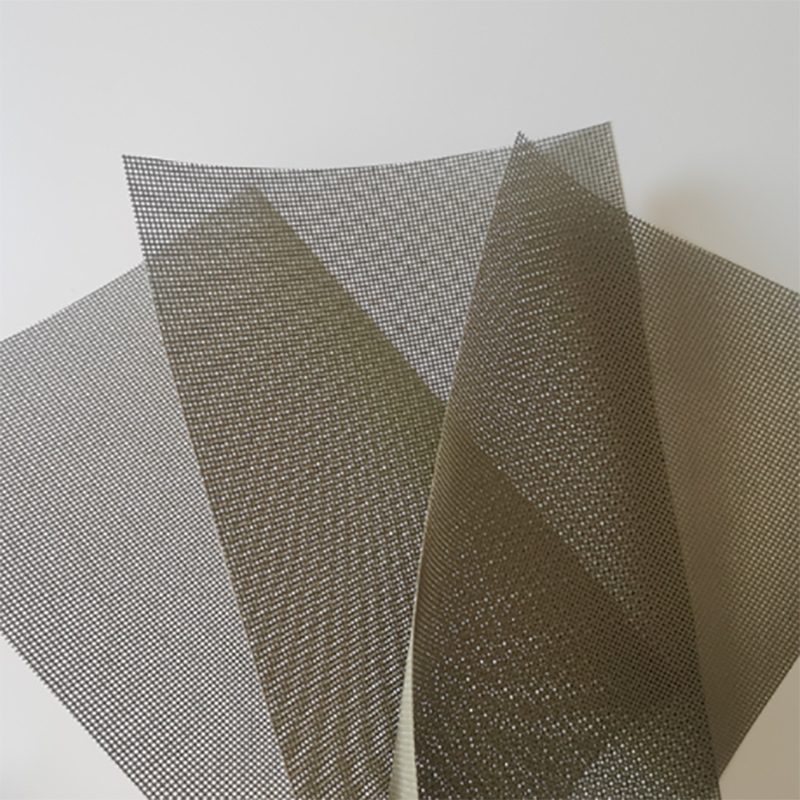

PVC-coated polyester mesh fabric can provide a degree of impact protection in certain applications, but its effectiveness in this regard depends on several factors, including the thickness and quality of the PVC coating, the weave pattern of the fabric, and the specific conditions of use. Here are some considerations:

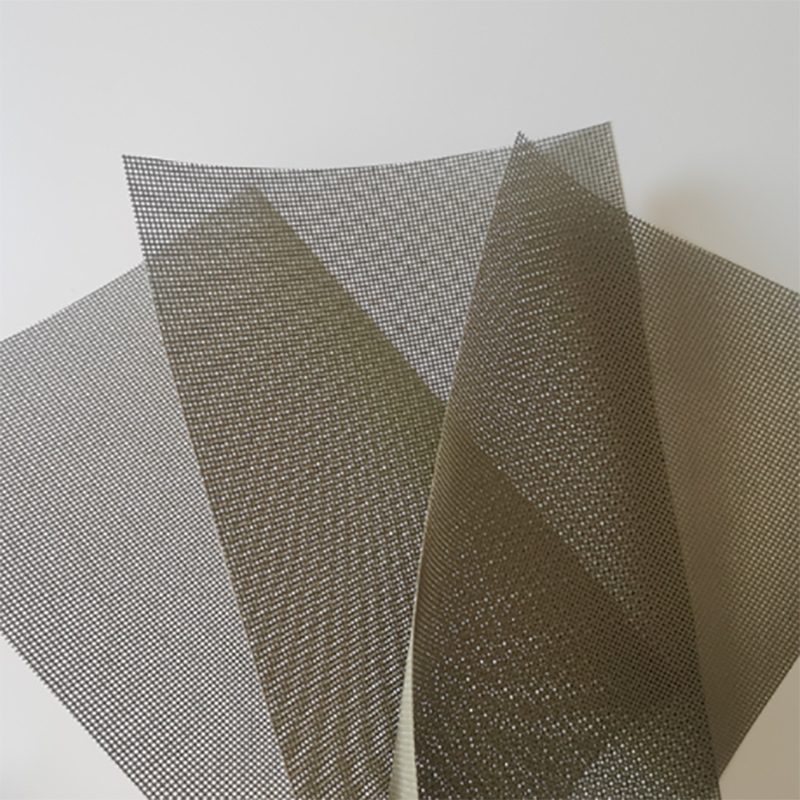

PVC Coating Thickness: The thickness of the PVC coating plays a significant role in determining the fabric's ability to withstand impacts. Thicker coatings tend to offer better impact resistance. If impact protection is a primary concern, you may want to choose PVC-coated polyester mesh fabric with a thicker PVC layer.

Weave Pattern: The weave pattern of the fabric can affect its ability to absorb or disperse impacts. Tighter weave patterns or specialty weaves designed for durability and strength can provide better impact protection than more open weaves.

Application: The intended application of the fabric is crucial. PVC-coated polyester mesh fabric can be used in various applications, including safety netting, fencing, and barriers. In some cases, it may serve as a protective barrier against falling objects or impacts. However, for high-impact applications, such as those involving heavy machinery or construction, specialized impact-resistant materials may be more suitable.

Support Structure: The fabric's ability to provide impact protection can be enhanced by the design and construction of the support structure. For example, in safety netting applications, the fabric is often installed with proper tension and anchoring to absorb and distribute impact forces.

Thickness of Material: Thicker and heavier variants of PVC-coated polyester mesh fabric may provide better impact resistance compared to thinner materials. The choice of material thickness should align with the expected impact forces in the specific application.

Quality and Certification: Look for PVC-coated polyester mesh fabric that meets relevant safety and impact resistance standards, especially if it will be used in safety-critical applications. Certification or testing documentation can provide assurance of the fabric's performance under impact.

Proper Installation: Proper installation techniques are essential for optimizing impact protection. This includes ensuring that the fabric is securely anchored and tensioned to distribute impact forces effectively.

Regular Inspection: Regular inspection and maintenance of the fabric are important to identify any damage or wear that could compromise its impact protection capabilities. Damaged sections should be repaired or replaced promptly.

While PVC-coated polyester mesh fabric can offer some degree of impact protection in specific applications, it's essential to consider the fabric's limitations and suitability for the intended use case. For high-impact environments or situations where safety is a primary concern, consulting with experts and considering specialized materials designed for impact resistance may be necessary to ensure adequate protection.

English

English عربى

عربى