PVC (Polyvinyl Chloride) tarpaulin material exhibits varying degrees of flexibility depending on its formulation, thickness, and environmental conditions, especially in cold weather. Here are key considerations regarding the flexibility of PVC tarpaulin material:

Factors Affecting Flexibility

Material Formulation:

The type and quality of PVC resin used in the tarpaulin formulation significantly impact its flexibility.

Flexible PVC formulations typically include plasticizers that improve elasticity and flexibility, especially at lower temperatures.

Thickness:

Thicker PVC tarpaulin materials may be less flexible compared to thinner variants due to increased material stiffness.

However, the addition of plasticizers can mitigate stiffness and maintain flexibility across different thicknesses.

Environmental Conditions:

PVC tarpaulin materials can become stiffer in cold weather conditions due to reduced mobility of polymer chains.

Flexible formulations and the use of appropriate plasticizers help maintain flexibility even in sub-zero temperatures.

Performance in Cold Weather

Cold Crack Resistance:

PVC tarpaulin materials are often tested for cold crack resistance, which refers to their ability to resist cracking at low temperatures.

Quality PVC tarpaulins designed for outdoor use typically have specifications indicating their resistance to cold cracking, often down to -30°C (-22°F) or lower.

Application Considerations:

Flexibility is crucial for applications requiring easy handling, folding, and deployment in cold climates, such as winter covers, outdoor enclosures, and tents.

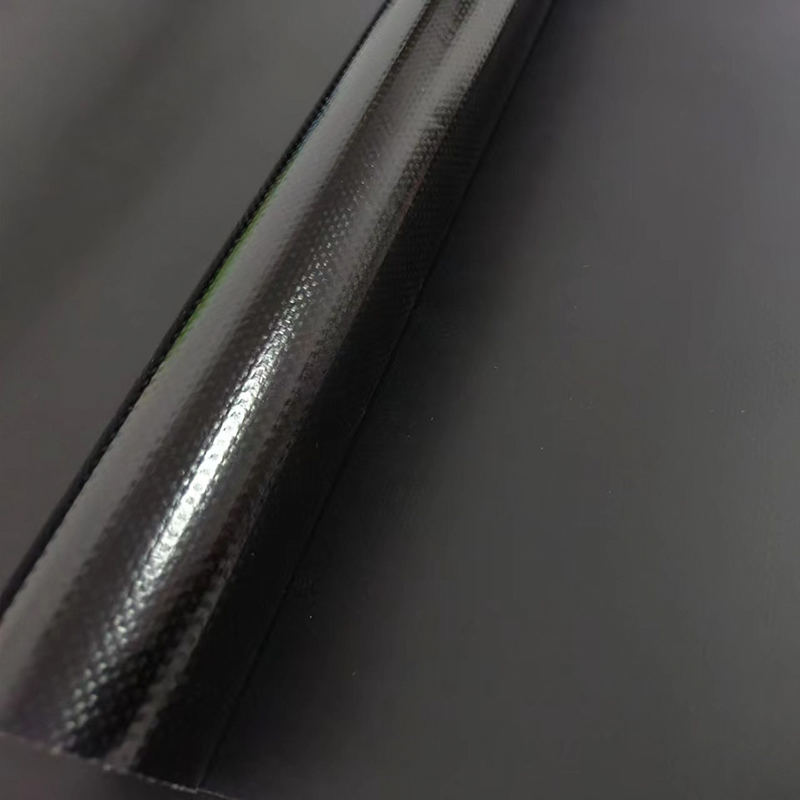

Reinforced PVC tarpaulin materials with fabric backings or mesh reinforcements maintain flexibility while enhancing strength and tear resistance.

English

English عربى

عربى