PVC-coated polyester mesh: a versatile material driving innovation in construction and industry

As the demand for high-performance, multi-purpose materials increases in the construction and industrial fields, PVC Coated Polyester Mesh Fabric has become a popular choice due to its excellent durability, flexibility and wide range of application scenarios. innovative materials. This material is widely used in architectural shading, advertising displays, industrial filtration and other fields. Its excellent tensile strength, weather resistance and cost-effectiveness are driving the rapid development of the industry.

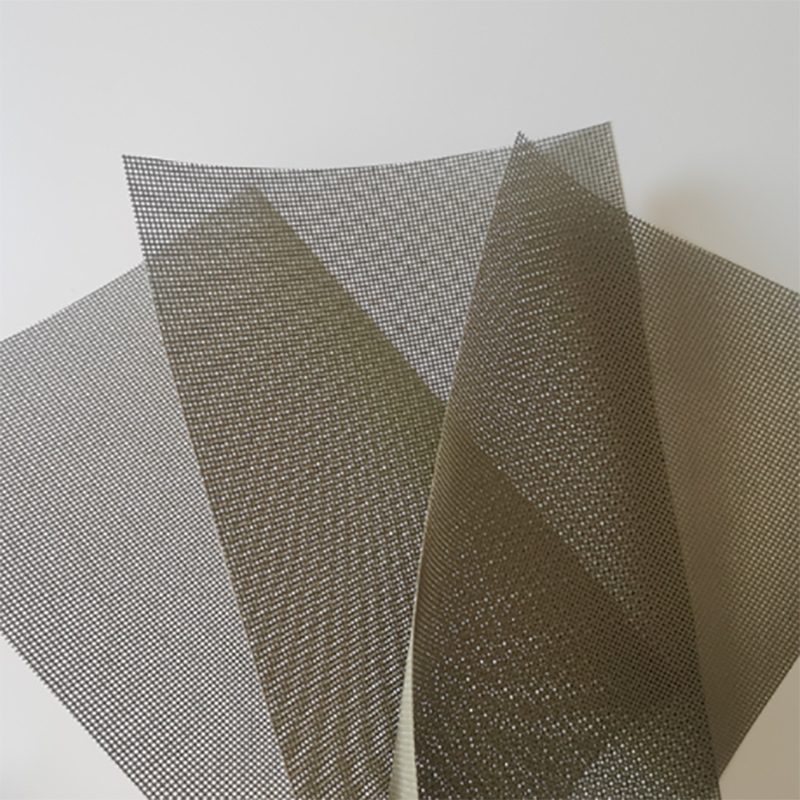

High-strength polyester fiber base fabric and surface-covered PVC coating. The polyester fiber gives the mesh extremely high tensile strength and flexibility, while the PVC coating provides excellent waterproofing, corrosion resistance and UV resistance. Through this structural design, PVC-coated polyester mesh can maintain stable physical properties and extend its service life in harsh environments.

The use of PVC coating gives the material good fire resistance and easy cleaning properties. Whether in building curtain wall applications or industrial filtration equipment, the material's durability and low maintenance costs are significant advantages.

In the construction field, PVC-coated polyester mesh is widely used in sunshade systems and tensile structures. It is often used to make products such as awnings, building exterior cladding and temporary structural tents. Due to its high strength, breathability and good wind resistance, the material can effectively regulate the internal temperature of the building and reduce energy consumption, thus enabling a more environmentally friendly building design. In addition, the mesh surface is smooth and easy to install and remove, making it an ideal material for building temporary structures.

The advertising industry also uses PVC-coated polyester mesh extensively to produce outdoor billboards, banners, flags, etc. Because the material is resistant to wind, rain and sunlight, it is ideal for large-format advertising that will be exposed to outdoor environments for extended periods of time. In addition, PVC coating provides an ideal surface for printing, allowing images and text to remain clear and colorful. The material is also extremely tear-resistant, ensuring the display remains strong and reliable in harsh weather conditions.

In industrial applications, PVC-coated polyester mesh is often used as filter materials, safety nets and isolation nets. Its resistance to corrosion and wear makes it an ideal choice in industrial environments, especially in chemical plants, mines and other scenarios where long-term filtration and safety protection are required. The material can also be tailored to specific needs with pore size and coating thickness to meet the requirements of different industrial filtration standards.

With the increasing global awareness of environmental protection, the sustainability of PVC-coated polyester mesh is becoming a focus of attention in material production and application. Many manufacturers are beginning to develop environmentally friendly PVC coatings that reduce the use of harmful chemicals during production while ensuring that the material can be recycled or safely disposed of at the end of its life cycle. In addition, the material's long life and low maintenance requirements also indirectly reduce resource waste and energy consumption, in line with the current trend of green building and sustainable development.

Technological innovations in the PVC coated polyester mesh industry are driving improvements in the material's performance. For example, new nanocoating technology can give materials stronger antifouling, antifungal and antibacterial properties, giving them broad application potential in medical environments, food processing and industrial sites with high cleanliness requirements. In addition, by optimizing the production process, manufacturers can provide a more diverse selection of colors and patterns to meet the individual needs of architects and designers.

From the perspective of market prospects, as industries such as global construction, advertising, and industrial filtration continue to expand, the demand for PVC-coated polyester mesh is expected to grow steadily. Especially in emerging markets, the acceleration of construction and infrastructure construction has promoted the widespread application of this material and increased its market share.

Although PVC coated polyester mesh excels in many areas, it still faces some challenges. First of all, the environmental protection issues of PVC materials need to be further solved. Although there is currently research and application of environmentally friendly PVC, energy consumption and pollution control during the production process still need to be further improved. Secondly, market competition is becoming increasingly fierce, and manufacturers need to continue to innovate, improve material performance and reduce costs to maintain market competitiveness.

With the further development of smart materials and manufacturing technology, PVC-coated polyester mesh is expected to be used in a wider range of fields. By combining with technologies such as smart sensors and automation systems, the material may play a greater role in smart buildings, smart cities and other fields.

As a high-performance, multi-functional material, PVC-coated polyester mesh is showing a wide range of application potential in the construction, advertising and industrial fields. With the advancement of technology and the growth of market demand, this material has broad prospects and will continue to promote industry innovation and development, providing more reliable, economical and environmentally friendly solutions for construction and industry around the world.

You may also like

-

Tarp for Truck Cover

-

PVC Tarp for Truck Side Curtain

-

Vinyl Tarp for Trailer Cargo Covers

-

PVC Tarps for PartyEvent Tent

-

Tarp for Waterproof Sun Shade Canvas Tent

-

Tarp for Outdoor Activities Exhibition Tent

-

Tarp for Party Wedding Tent

-

Tarp for Animal Horse Livestock Shelter Outdoor Tent

-

Tarp for Industrial Storage Warehouse Workshop Tents

-

Tarp for Coal Mine Tent for Colliery

-

PVC Tarpaulin for Universal Outdoor Camping Side Awning

-

Outdoor Sunshade Canopy PVC Tarpaulin

简体中文

简体中文 English

English