PVC tarpaulin material has emerged as a versatile and durable solution across a variety of industries, offering robust performance in challenging environments. Known for its strength, flexibility, and resistance to harsh conditions, PVC (polyvinyl chloride) tarpaulin is a preferred choice for applications ranging from construction and agriculture to recreational and transportation uses. This article explores the properties, manufacturing process, and diverse applications of PVC tarpaulin material, highlighting its significance in modern industry.

Properties of PVC Tarpaulin Material

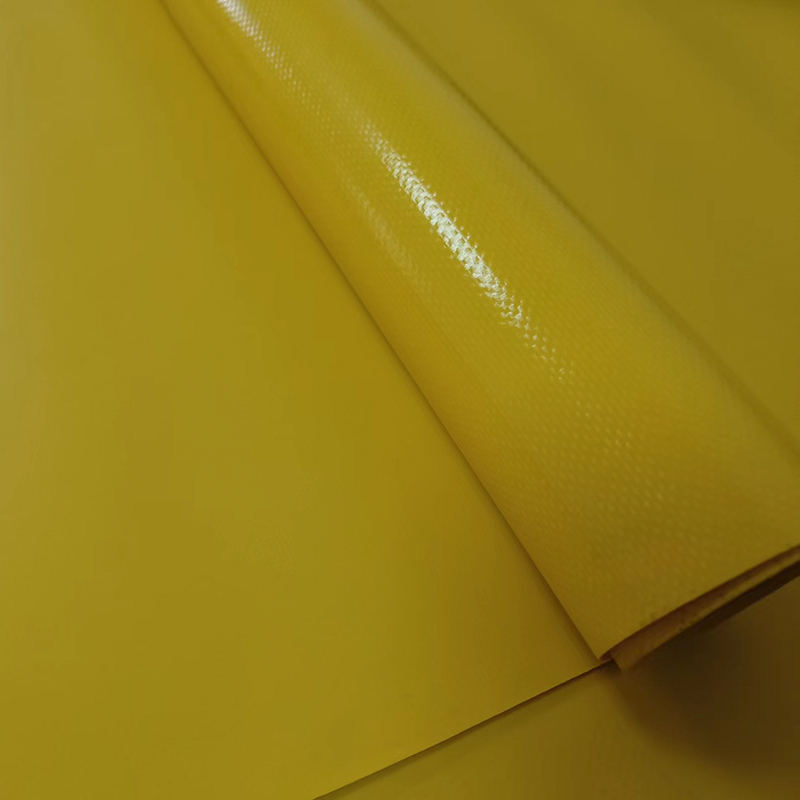

PVC tarpaulin is a high-strength, waterproof fabric coated with polyvinyl chloride to enhance its durability and functionality. Key properties include:

Durability: PVC tarpaulin is known for its exceptional strength and resistance to tearing, making it suitable for heavy-duty applications. It can withstand significant wear and tear, providing long-term reliability.

Water Resistance: One of the primary benefits of PVC tarpaulin is its ability to repel water, ensuring that the material remains effective in wet and rainy conditions. This makes it ideal for outdoor use.

UV Resistance: The material is treated to resist damage from ultraviolet (UV) radiation, preventing degradation and color fading when exposed to sunlight.

Flexibility: Despite its strength, PVC tarpaulin remains flexible and easy to handle, allowing for easy installation and transportation.

Chemical Resistance: PVC tarpaulin is resistant to many chemicals and pollutants, making it suitable for use in environments where exposure to hazardous substances is possible.

Temperature Tolerance: The material performs well in a wide range of temperatures, maintaining its integrity in both hot and cold climates.

Manufacturing Process

The production of PVC tarpaulin involves several steps to ensure its high quality and performance:

Base Fabric: The process begins with a base fabric, typically made of polyester or other strong fibers. This fabric provides the foundational strength of the tarpaulin.

PVC Coating: The base fabric is then coated with polyvinyl chloride. This coating can be applied through various methods, such as knife coating, calendaring, or extrusion. The PVC layer enhances the fabric's water resistance, durability, and other protective properties.

Heat Treatment: The coated fabric undergoes heat treatment to ensure proper bonding between the PVC and the base fabric. This step is crucial for achieving the desired strength and durability.

Finishing: Finally, the material may be treated with additional finishes, such as UV stabilizers or flame retardants, to enhance its performance in specific applications.

Applications of PVC Tarpaulin Material

The versatility of PVC tarpaulin material makes it suitable for a wide range of applications:

Construction: PVC tarpaulins are widely used in the construction industry for scaffolding covers, temporary shelters, and protective barriers. Their durability and weather resistance make them ideal for protecting construction sites and materials.

Agriculture: In agriculture, PVC tarpaulins serve as covers for greenhouses, haystacks, and livestock shelters. They protect crops and animals from adverse weather conditions and provide a controlled environment for growth.

English

English عربى

عربى